Micro-welded 90° elbow

The base material is 316L secondary smelted, and the body is engraved with a traceable base material code.

The key inner surfaces are visually inspected 100% with the aid of a magnifying glass and special lighting fixtures.

Surface Finish: BA ≤ 0.8μm; EP ≤ 0.3μm

Product Description: Pressure Resistance Coefficient: The rated working pressure is determined by the gasket material at room temperature.

Temperature Resistance Coefficient: For the joint, it is 537°C; for the nickel gasket, it is 315°C, and for the stainless steel gasket, it is 537°C.

Cleaning and Packaging: Ultrasonic cleaning is carried out in a clean room, and double-layer packaging is done in a dust-free room.

Vacuum Leakage Rate: It is determined by the sealing gasket. When using a silver-plated or copper gasket, the leakage rate is 4×10⁻⁹ std cm³/s; when using an unplated gasket, the leakage rate is 4×10⁻¹¹ std cm³/s.

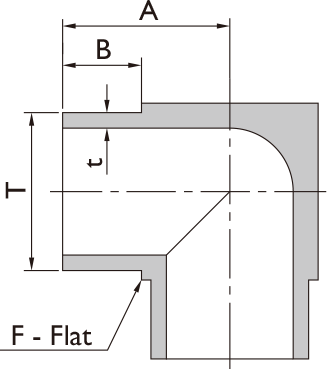

2D and 3D format drawings are available. If you have any needs, please contact the sales representative of Magnorco or the local authorized dealer.

The key inner surfaces are visually inspected 100% with the aid of a magnifying glass and special lighting fixtures.

Surface Finish: BA ≤ 0.8μm; EP ≤ 0.3μm

Product Description: Pressure Resistance Coefficient: The rated working pressure is determined by the gasket material at room temperature.

Temperature Resistance Coefficient: For the joint, it is 537°C; for the nickel gasket, it is 315°C, and for the stainless steel gasket, it is 537°C.

Cleaning and Packaging: Ultrasonic cleaning is carried out in a clean room, and double-layer packaging is done in a dust-free room.

Vacuum Leakage Rate: It is determined by the sealing gasket. When using a silver-plated or copper gasket, the leakage rate is 4×10⁻⁹ std cm³/s; when using an unplated gasket, the leakage rate is 4×10⁻¹¹ std cm³/s.

2D and 3D format drawings are available. If you have any needs, please contact the sales representative of Magnorco or the local authorized dealer.

- Size parameters

- Product Features