Company Profile

Suzhou Maiginuoke Clean Materials Co., Ltd. was established in 2012, specializing in the design, processing, manufacturing, and sales of various ultra-high cleanliness systems and precision components based on ultra pure metals as base materials.

The company is committed to providing customers with various high-quality and cost-effective standard parts and customized products, as well as high-quality full process supply chain management services.

We have a complete production line that integrates mechanical processing, TIG welding, and surface treatment; Having a 100&10K level clean room certified by a third-party to meet the welding, cleaning, testing, and packaging needs of ultra pure gas pipelines in the semiconductor industry; We have various testing equipment from top international brands.

The team possesses a complete set of professional capabilities in design, craftsmanship, manufacturing and processing, quality and process control, and supplier management; The personnel have excellent technical skills, rich experience, practical dedication, and have a good reputation in the industry. The company has obtained ISO9001 quality management system certification, TUV PED4.3 pipe production and welding certification, ISO3834 welding system certification, and has obtained multiple patents.

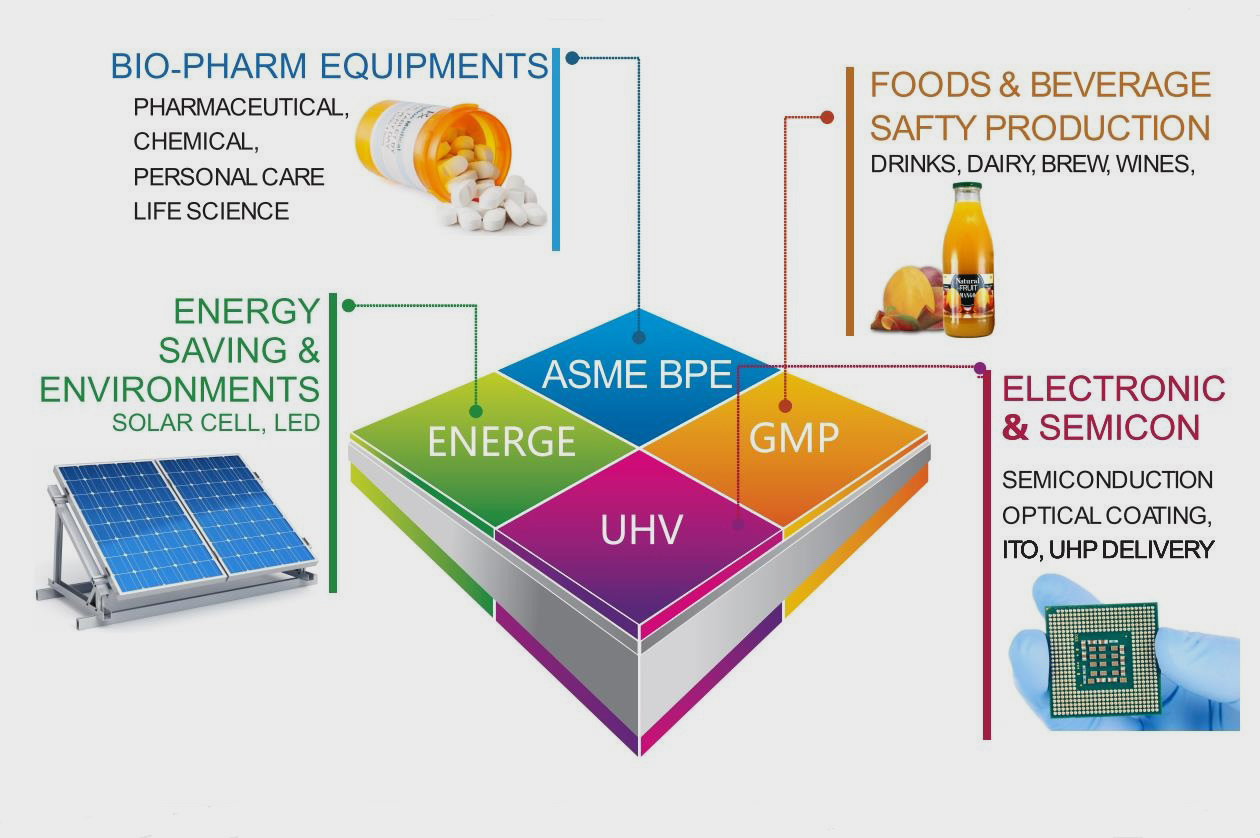

Magnoco adheres to a customer-oriented approach and provides extensive services to customers in industries such as biopharmaceuticals, food and beverage, precision chemicals, solar photovoltaics, semiconductor chips, flat panel displays, as well as scientific research and aerospace. With years of professional experience, we understand the strict requirements of these industries and have mature solutions. For example, regarding the cleanliness of the system and the positional accuracy of welded products, we have developed a comprehensive process plan and operating SOP. Magnoco will provide you with the best solution under your strict requirements to achieve your target needs.

Corporate culture

Mission Vision

Mission: To uphold the spirit of craftsmanship and meet the needs of customers.

Our innate curiosity and problem-solving culture have always driven us to work harder and provide more value to our customers. Maginoco is not just a company, we are also a family with a profound cultural heritage. We are happy to help you solve every big and small problem. If you need any assistance, we will be happy to serve you!

Vision: To stand out from the crowd because of us.

Our great vision is to stand out from the crowd because of us, and we hope to elevate the value of our customers' products through our efforts, thereby standing out in the market competition. Everyone at Megunoco has demonstrated a great vision that runs through the fabric of our company and ultimately translates into the standards we set for our products and customers.

Product series

Provide high-precision mechanical components and systems based on materials such as ultra pure stainless steel, titanium alloy, and Hasse alloy. Our products are widely used to serve customers in industries such as biopharmaceuticals, food and beverage, precision chemicals, solar photovoltaics, semiconductor chips, flat panel displays, as well as scientific research and aerospace.

Team Capability

The team possesses a complete set of professional capabilities in design, craftsmanship, manufacturing and processing, quality and process control, and supplier management; The personnel have excellent technical skills, rich experience, down-to-earth dedication, and have a good reputation and good reputation in the industry.

Mechanical processing capability

Magnoco is committed to precision machining and welding, mastering the programming and manufacturing standards of precision components. It has internationally renowned car milling equipment and UHV cleaning production lines, and has applied for multiple manufacturing patents. It can process various process vacuum chambers and supporting vacuum and gas pipelines, providing comprehensive technical support services and solutions.

Welding ability

Magnoco is one of the few manufacturers in the pan semiconductor industry that possesses both precision machining and precision welding capabilities in the precision machining supporting system. The company has equipment for vacuum brazing, argon arc welding, laser welding, etc. Hire IIW and AWS dual certified welding engineers to assess and control welding processes. At present, there are 30 welding technicians who can perform automatic welding, semi-automatic welding, and manual welding on products according to process requirements.

Surface treatment capability

The company has a relatively complete set of surface treatment special processes and independent patented technologies. It can achieve various high cleanliness, super strong corrosion resistance, and breakdown voltage resistance process technologies and detection capabilities, including chemical cleaning, anodizing, electrolytic polishing, nickel electroplating, chemical nickel plating, ceramic spraying, mechanical polishing, etc.

Precision cleaning capability

Megunoco has a 100000 level cleanroom pure water cleaning line and a semiconductor level 100 level cleanroom ultra pure water cleaning line, which can meet the cleaning needs of various processes.

Clean room welding assembly cleaning

Megunoco has clean rooms certified by third-party certification at levels 100, 1000, and 10000. It can meet the entire process of cutting, welding, cleaning, assembly, testing, and packaging for ultra pure gas pipelines, gas path panels, and precision components in the semiconductor industry.

Detection capability

Magnoc has a wealth of dimensional inspection capabilities, integrating anime and three-dimensional programming, manual detection, reverse engineering, big data analysis and application, to provide customers with reliable inspection data. The main testing capabilities include but are not limited to: FARO coordinate measuring instrument from the United States, Mitutoyo height gauge from Japan, Mitutoyo surface roughness meter from Japan, OLYMPUS material analyzer from the United States, Seven permeability detector from the United States, and AGILENT leak detector from the United States. Membrane thickness gauge, endoscope, salt spray test, general physical and chemical experiments, etc.

Enterprise Qualification

Our outstanding performance

The products are mainly supplied to high-end technology industries such as wafer manufacturing, chip manufacturing, LCD displays, fiber optic communication, solar photovoltaics, scientific research institutions, as well as biopharmaceuticals, food and other industries, providing cost-effective technical solutions.