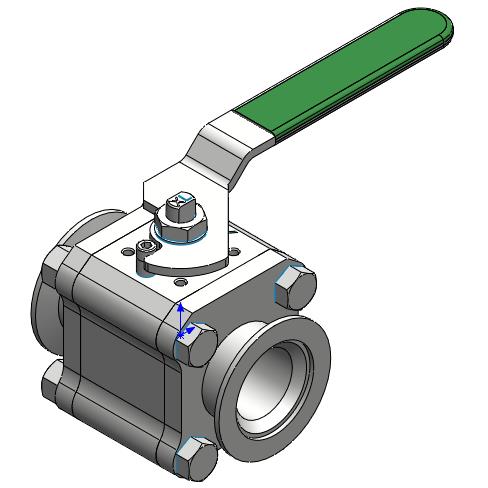

Integrated High-temperature-resistant Vacuum Ball Valve

The valve body is precisely processed in one piece, and it is the designated model for high-temperature equipment such as MOCVD.

With a special internal structural design, it has a self-cleaning function, effectively preventing the deposition of materials.

This ensures a clean dynamic seal and prevents failures caused by contamination.

Leakage rate: ≤1x10-9 std. cc/sec. He.

Valve body material: SUS316L.

Sealing material of the valve core: PTFE.

Temperature range: Intermittent baking at -25°C~≤205°C.

It features a modular design, making maintenance convenient.

The valve body is equipped with a positioning lock, which is convenient for positioning.

It has a larger flow conductance CV value design compared to similar valves and can be used as a temporary sample window.

It provides a variety of connection methods such as internal thread NPT, KF flange, and socket welding.

Both manual and pneumatic driving methods are available.

The standard maintenance kit allows for easy maintenance of the valve.

2D and 3D models can be provided, and non-standard customization is accepted. If you have any needs, you can consult our sales engineers.

Note: The ball valve may be very "stiff" during the initial operation, which is a normal phenomenon.

With a special internal structural design, it has a self-cleaning function, effectively preventing the deposition of materials.

This ensures a clean dynamic seal and prevents failures caused by contamination.

Leakage rate: ≤1x10-9 std. cc/sec. He.

Valve body material: SUS316L.

Sealing material of the valve core: PTFE.

Temperature range: Intermittent baking at -25°C~≤205°C.

It features a modular design, making maintenance convenient.

The valve body is equipped with a positioning lock, which is convenient for positioning.

It has a larger flow conductance CV value design compared to similar valves and can be used as a temporary sample window.

It provides a variety of connection methods such as internal thread NPT, KF flange, and socket welding.

Both manual and pneumatic driving methods are available.

The standard maintenance kit allows for easy maintenance of the valve.

2D and 3D models can be provided, and non-standard customization is accepted. If you have any needs, you can consult our sales engineers.

Note: The ball valve may be very "stiff" during the initial operation, which is a normal phenomenon.

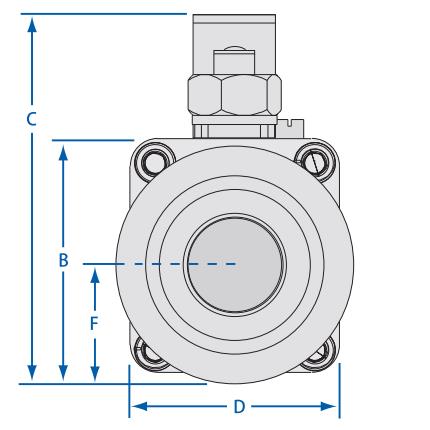

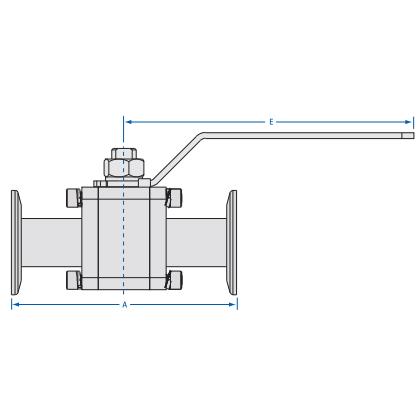

- Size parameters

- Product Features