Introduction to W-shaped and C-shaped seals

2024-07-19 16:51:55 Source: Maginoco website visit:

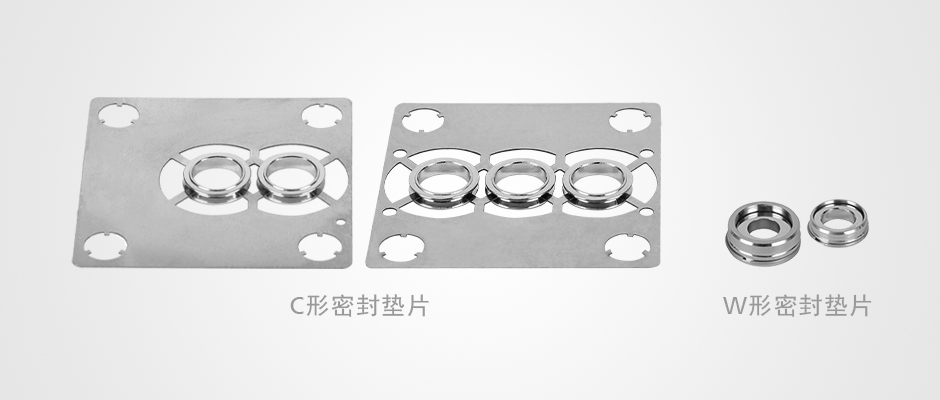

W-shaped and C-shaped seals are commonly used in modular gas systems (IGS) for semiconductor equipment, which consist of components such as diaphragm valves, one-way valves, pressure reducing valves, filters, pressure sensors, mass flow controllers, and base blocks. These components are generally surface mounted, and their sealing forms can be divided into W-shaped seals and C-shaped seals. Choosing the appropriate sealing form is crucial to ensure the sealing performance of the system. So what are the similarities and differences between W-shaped seals and C-shaped seals?

The similarities between W-shaped seal and C-shaped seal

The difference between W-shaped seal and C-shaped seal

The cross-section of the C-shaped sealing gasket looks like the letter "C", with two flat convex sealing surfaces on both sides. When tightened appropriately, the top and bottom of the gasket are respectively compressed by surface mounting components (such as C-shaped sealing valve body) and the hardened sealing surface of the base block, forming a seal. In addition, when installing the C-shaped sealing gasket, a bracket can be used to locate and install multiple gaskets at once.

For any modular gas system (IGS), W-shaped or C-shaped seals can meet the requirements, but due to the implementation of different SEMI standards, the structure of the sealing gasket and sealing surface is different. Users can choose the corresponding W-shaped or C-shaped seal according to their usage habits and the sealing form of the components.